Hyperweathering: Enhanced Rock Weathering for Climate Change Mitigation Meets Phytomining Technology

Hyperweathering: Forging a Carbon-Negative Future with Critical Minerals and Enhanced Rock Weathering Introduction: Addressing Intertwined Global Crises Humanity stands at a critical juncture, facing the dual and interconnected crises of accelerating climate change and escalating resource scarcity. The scientific consensus, powerfully articulated by the Intergovernmental Panel on Climate Change (IPCC) and corroborated by the latest data from the World Meteorological Organization and Copernicus, confirms that 2024 was the warmest year on record, with the global average temperature exceeding 1.5°C above pre-industrial levels for the calendar year. Atmospheric carbon dioxide concentrations continue their relentless climb, reaching approximately 422.1 ppm in 2024. The Global Carbon Budget 2024 report underscores the urgency, revealing that global fossil fuel CO2 emissions hit a new record in 2024, leaving a perilously small carbon budget – estimated at roughly six years at current rates for a 50% chance of limiting warming to 1.5°C. This stark reality necessitates a paradigm shift in our approach. The IPCC’s assessments make it unequivocally clear: deep emissions reductions alone are insufficient. We must actively develop and deploy scalable technologies for Carbon Dioxide Removal (CDR) to draw down legacy emissions and address hard-to-abate sectors. Concurrently, the vital transition to a green energy economy—our primary weapon in decarbonization—hinges on an unprecedented supply of critical minerals. The International Energy Agency (IEA) projects that demand for metals like nickel, lithium, and cobalt could skyrocket by up to 1,900% for nickel and 4,200% for lithium by 2040, as these are foundational to electric vehicles, battery storage, and renewable energy infrastructure. Traditionally, these monumental challenges have been tackled in silos. Carbon removal strategies pursued avenues like direct air capture or afforestation, while critical minerals were sourced via conventional mining—a sector grappling with significant environmental and social footprints. Metalplant is charting a new, integrated course. We have pioneered “Hyperweathering,” a breakthrough approach that synergistically combines Enhanced Rock Weathering (ERW) with phytomining, not only to sequester atmospheric CO₂ but also to sustainably produce essential critical minerals with a net-carbon-negative footprint. Our flagship product, NegativeNickel™, embodies this vision. This article delves into the robust scientific underpinnings of hyperweathering. It explores its profound potential for climate change mitigation, its positioning as a responsible geoengineering technique, and its pivotal role in fueling the green energy transition through the sustainable provision of critical minerals. Metalplant’s innovation represents a transformative step in how we conceive resource utilization and carbon stewardship, demonstrating that ecological restoration and industrial necessity can be mutually reinforcing. The Science of Enhanced Rock Weathering: Accelerating Nature’s Carbon Sink Natural Carbon Sequestration: Earth’s Slow Geochemical ThermostatTo appreciate the innovation of Enhanced Rock Weathering, one must first understand Earth’s natural long-term carbon cycle. The geological weathering of silicate rocks is a primary mechanism by which the planet has regulated atmospheric CO₂ over eons. When rainwater, slightly acidic from dissolved atmospheric CO₂, interacts with silicate minerals, a series of chemical reactions ensues. These reactions convert gaseous CO₂ into stable bicarbonate ions (HCO₃⁻). These ions are transported by rivers to the oceans, where marine organisms utilize them to form calcium carbonate shells and skeletons. Upon their demise, these organisms sink, eventually forming limestone and other carbonate rocks, effectively sequestering carbon for geological timescales – hundreds of thousands to millions of years. This natural process, while profoundly important, operates on timescales far too slow to counteract the current anthropogenic surge in CO₂ emissions. Globally, natural silicate weathering is estimated to remove only about 0.3 gigatons of CO₂ annually, a small fraction of the over 40 gigatons emitted by human activities each year. Enhanced Rock Weathering seeks to dramatically accelerate this natural carbon sink to achieve climate-relevant CO₂ removal within human timescales. As the Department of Energy’s Carbon Negative Shot initiative highlights, developing cost-effective and scalable CDR solutions like ERW is paramount. Metalplant’s Hyperweathering: A Synergistic Leap ForwardMetalplant’s proprietary hyperweathering process significantly advances ERW technology. Conventional ERW typically involves spreading crushed silicate rocks, such as basalt or olivine, onto agricultural lands, relying on natural processes for weathering and carbon sequestration. Hyperweathering, however, employs an actively managed, multi-faceted strategy to boost both the rate and overall efficiency of CO₂ removal, integrated with phytomining. Our process meticulously begins with the sourcing and preparation of olivine, a magnesium iron silicate mineral ((Mg,Fe)₂SiO₄). Olivine is chosen for its relatively rapid weathering rate compared to other silicate minerals and its abundant global availability. Metalplant has secured exclusive access to a multi-billion tonne, high-purity olivine deposit (approximately 80% forsterite olivine, 0.33-0.343% nickel) adjacent to our Albanian operations, supplied at a very low cost by a co-founder. This olivine undergoes proprietary grinding processes to achieve an optimal particle size (sub-100 micron) that maximizes reactive surface area while managing potential dust. The process also includes mechanical gravimetric operations to remove loose chromite, at a net cost of approximately $4/tonne of olivine after accounting for potential chromium byproduct sales. The processed olivine is then applied to carefully selected nickel-bearing serpentine soils – the native habitat of the hyperaccumulator plants we utilize. Metalplant’s innovation lies in moving the farm to the rocks, operating on ultramafic soils that are themselves derived from these minerals. We employ several interventions to accelerate weathering: Optimized Application & Soil Interaction: We target substantially higher application rates (e.g., 100 tonnes/hectare) than some conventional ERW proposals. This is driven by the need to replenish nickel extracted by phytomining, but also contributes to potentially the highest density ERW-based carbon removal per land unit per year. The olivine is mixed into the soil where elevated CO₂ levels from root respiration and microbial activity, along with direct water exposure, accelerate dissolution. Biocatalyst and Chelator Research: While the draft mentions partnerships with Sheffield University for microbial communities and the Leverhulme Centre for chelator-enhanced weathering, Metalplant’s provided background files also mention exploring iron chelators as a biotechnology to accelerate weathering, referencing a study showing a 2.5x increase in basalt weathering, suggesting even greater potential for pure olivine. Hyperaccumulator Plant Integration (Phytomining): This is the cornerstone of Metalplant’s unique hyperweathering system. We utilize specific nickel hyperaccumulator plant species, particularly a

Metalplant Enhanced Rock Weathering Podcast

Podcast Episode Summary: This episode explores an innovative approach to carbon removal that goes beyond simply separating greenhouse gases from the air, by also creating other valuable products. It features Eric Matzner, co-founder of a new venture called Metalplant, which is making its public debut. Metalplant combines hyperaccumulator plants and enhanced rock weathering to extract nickel from soil and crushed rock while simultaneously removing atmospheric carbon. The discussion delves into the economics of co-producing nickel alongside carbon offsets, addressing the broader challenges of scaling carbon removal, and Matzner’s views on vertical integration for quality and cost control. The episode highlights Metalplant’s initial operations in Albania, leveraging local olivine resources on non-arable land and generating employment. A significant portion of the conversation focuses on a potential “intellectual crisis” within the carbon removal industry: how should it handle methodologies that co-produce significant value in addition to carbon removal? Key questions include whether these ventures should still sell carbon credits, if this creates unfair competition for companies solely focused on carbon removal, and whether financial additionality is the correct framework for intervention, if intervention is needed at all. The episode probes whether conventional additionality principles might unduly hold back co-producers whose scaling is desperately needed.

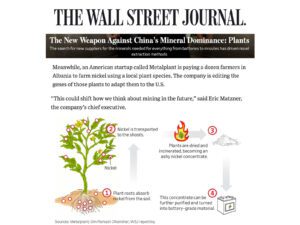

The New Weapon Against China’s Mineral Dominance: Plants – Metalplant Featured in the Wall Street Journal

“This could shift how we think about mining in the future,” said Metalplant Co-Founder Eric Matzner in discussing how hyperaccumulator plants offer a new method to recover metals from unconventional soils and economical ways.

White Paper: The Overlooked Magnesium Advantage in Enhanced Rock Weathering

The Overlooked Magnesium Advantage in Enhanced Rock Weathering How Magnesium-Rich Silicates Like Olivine Resist Carbonate Formation and Are More Efficient Per Tonne as Compared to Calcium-Based Mineral Exploring the Untapped Potential in Enhanced Rock Weathering: The Magnesium Advantage You may be familiar with enhanced rock weathering (ERW) as a promising method for carbon dioxide removal. Much of the current discussion and deployment – perhaps around 95% of ERW efforts – understandably focuses on calcium-based minerals, which have been more readily adopted. However, a deeper look into the geochemistry reveals that magnesium-rich minerals like olivine possess inherent advantages in efficiency, which can translate to lower operational costs and a higher density of carbon removal per tonne of rock applied. Historically, these highly efficient magnesium minerals have often been sidelined due to concerns about their naturally occurring trace nickel content, particularly when considering application on agricultural lands. With innovative approaches, such as Metalplant’s integration of phytomining to recover nickel and a focus on operating on existing nickel-bearing soils, the path is clearing to re-evaluate and harness the significant CO₂ removal potential of fast-weathering, magnesium-rich minerals like olivine. This white paper, “The Overlooked Magnesium Advantage in Enhanced Rock Weathering,” delves into the scientific reasons why magnesium-based feedstocks offer distinct benefits. After reading, the unique advantages of magnesium will no longer be overlooked. Inside, you’ll discover detailed explanations of why magnesium-rich silicates are often superior, including: Superior Resistance to Premature Carbonate Formation: Learn how magnesium’s strong bond with water (its hydration shell) creates a significant kinetic barrier—requiring about 330 kJ/mol more energy to overcome than for calcium—preventing it from easily forming solid carbonate minerals in typical soil conditions. This ensures the captured carbon (as dissolved bicarbonate) remains mobile. Enhanced Permanence and Mobility of Sequestered Carbon: Unlike calcium, which can precipitate as calcium carbonate in soils (potentially re-releasing some CO₂ and immobilizing alkalinity locally), magnesium keeps the bicarbonate alkalinity dissolved and transportable through waterways to the ocean for durable, long-term storage. More Reliable Ocean Alkalinity Enhancement: Understand how magnesium’s much longer residence time in the ocean and its resistance to forming marine carbonates contribute more effectively and persistently to increasing the ocean’s carbon storage capacity and buffering against acidification. Greater CO₂ Removal Efficiency Per Tonne: Explore the data (including findings from lifecycle analyses like Breunig et al., 2024) showing that magnesium-rich minerals can sequester significantly more CO₂ per tonne of rock (e.g., olivine achieving ~760 kg net CO₂/tonne) compared to many calcium-based alternatives (125-160 kg net CO₂/tonne). Reduced Logistical and Economic Burdens: See how the higher efficiency per tonne translates directly into lower requirements for mining, grinding, transportation, and application, making ERW projects potentially more cost-effective and scalable. Simplified Monitoring and Verification: Discover why the tendency of magnesium to remain in solution can lead to more straightforward and reliable methods for monitoring carbon removal and verifying the transport of alkalinity. Benefits for Soil Processes: Learn how, by resisting extensive precipitation, magnesium can help maintain soil pore connectivity and hydraulic conductivity, supporting healthy soil functions (when applied with consideration for overall soil chemistry). Gain a comprehensive understanding of the fundamental geochemistry that makes magnesium-rich minerals a highly promising, and arguably superior, option for scalable and effective carbon dioxide removal. Download the full white paper below to explore the science in detail. Download White Paper

“Mining flowers for nickel” – New Scientist Magzine Features Metalplant’s Nickel Hyperaccumulator Harvest

Metalplant’s nickel harvest was featured in the July 13-19, 2024 Print issue of New Scientist magazine: “On a recent afternoon in northern Albania, workers gathered armfuls of freshly cut shrubs covered in yellow flowers, leaving them to dry in the sun. This was no ordinary harvest, however. The farm is both a mine, growing plants that accumulate nickel metal in their leaves and stems, and a carbon sink, its soil spread with crushed rocks that remove carbon dioxide from the atmosphere… The idea of mining with plants isn’t new. But Metalplant is combining this “phytomining” with a method of removing CO2 from the atmosphere called enhanced rock weathering, which involves spreading rock dust on fields. This dust can both capture CO2 and replenish the nickel taken up by the plants.”

Metalplant’s Proposal Awarded $1.72m by DOE ARPA-E to Enhance Hyperaccumulators and Spur Nickel Phytomining in the USA

SAN FRANCISCO, CA, UNITED STATES, September 19, 2024 / — Metalplant, a leading phytomining startup, and partner, Verinomics, a plant genetic editing firm, have been awarded $1.72 million by the U.S. Department of Energy (DOE) Advanced Research Projects Agency-Energy (ARPA-E) as part of its PHYTOMINES Exploratory Program. The project has a goal of developing sterile, higher-nickel yielding hyperaccumulator cultivars that will enable the development of a nickel phytomining industry in the United States. Phytomining is the process of farming low-grade nickel soils with hyperaccumulator plants and then recovering pure nickel products from biomass using metallurgical processes. It is essentially mining with plants, allowing photosynthesis to power the purification of the nickel from low to high grades. Nickel hyperaccumulators accumulate nickel in their tissues at rates greater than 0.1% of dry weight. Metalplant utilizes a species that can already accumulate above 2% nickel by dry weight. When the biomass is harvested and then processed with thermal treatment, the resulting ash can be as high as 20% nickel, comparable to some of the richest nickel ores in the world. Nickel was classified as a critical mineral by the DoE in 2023 because it is a crucial component in stainless steel production and is increasingly important for electric vehicle (EV) batteries. With the rapid growth of the EV market, demand for nickel is expected to surge in the coming years. The US has limited conventional nickel resources and only one active primary nickel mine, which is scheduled to close by the end of the decade. However, the US has vast swaths of soils bearing nickel that could be recovered economically through high-yield phytomining if a suitable hyperaccumulator were able to be utilized. A suitable hyperaccumulator is a species that is fast-growing, has high biomass and a high percentage of nickel. The most widely studied and optimal plants known to date are from the Brassicaceae family, and are native to Albania, where Metalplant (a US-domiciled company with an Albanian subsidiary) operates phytomining farms. Twenty years ago, a plant species related to the one Metalplant utilizes was brought to the United States, and successful trials were carried out, however, the plant was declared invasive, leading to a cessation of operations. Metalplant’s selected proposal involves working with Verinomics to genetically modify the plants by means of a non-GMO method, to introduce sterility in order to prevent invasive behavior, and to allow for modifications that can significantly increase nickel yields. The production of sterile, high-yielding nickel hyperaccumulator plants that can be safely cultivated on American soil is a breakthrough that could pave the way for a new, environmentally friendly nickel industry in the US. Unlocking previously uneconomic, domestic sources of nickel addresses national security risks in the critical mineral supply chain by reducing dependence on foreign sources. The potential impact of this technology extends beyond just nickel production. The same principles could be applied to other critical metals, offering a blueprint for sustainable metal extraction that could shift global balances by opening up unconventional and even waste resources for use. Metalplant thanks the DOE and ARPA-E for their foresight in developing this program that provides crucial support to spur phytomining technology in the USA to develop a secure, low-carbon domestic nickel supply chain. This program ensures that the United States can again become a leader in a technology originally developed here, but that was no longer being implemented commercially, and Metalplant is excited to onshore their technology and lead in the successful commercialization of nickel phytomining.