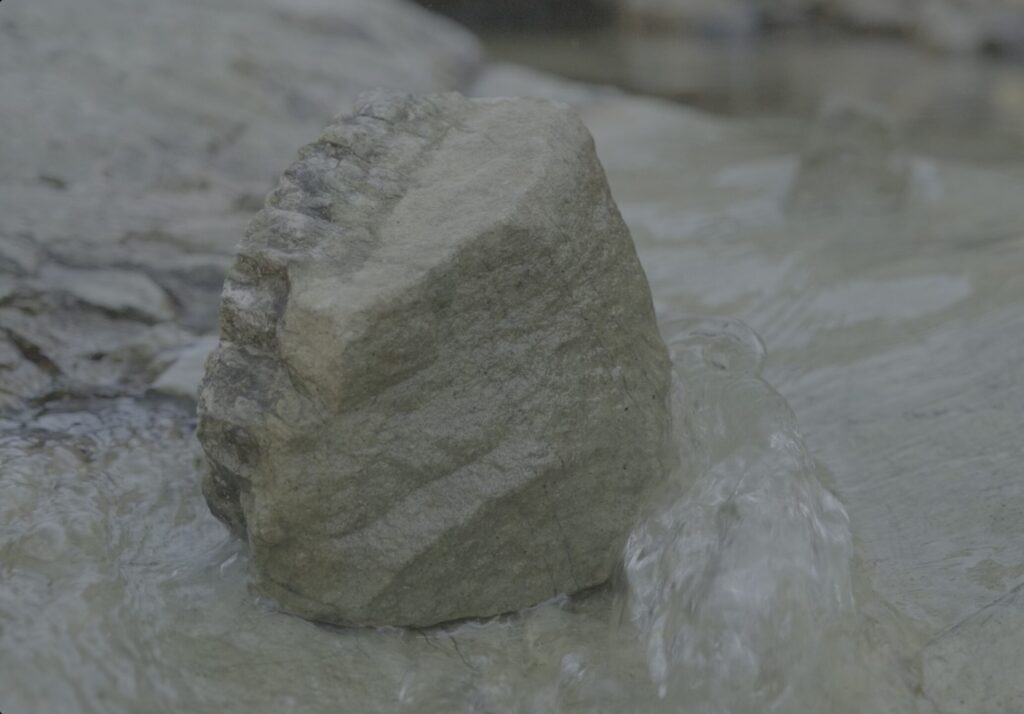

NegativeNickel™ – Carbon-Negative Nickel

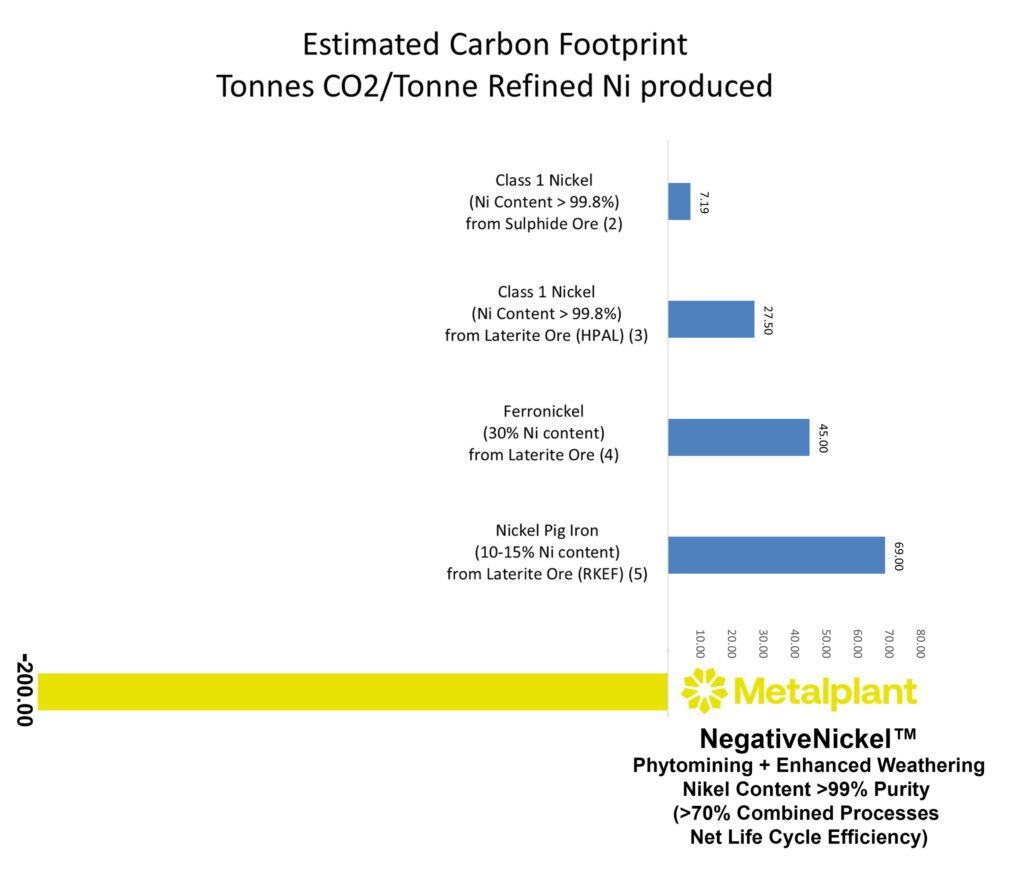

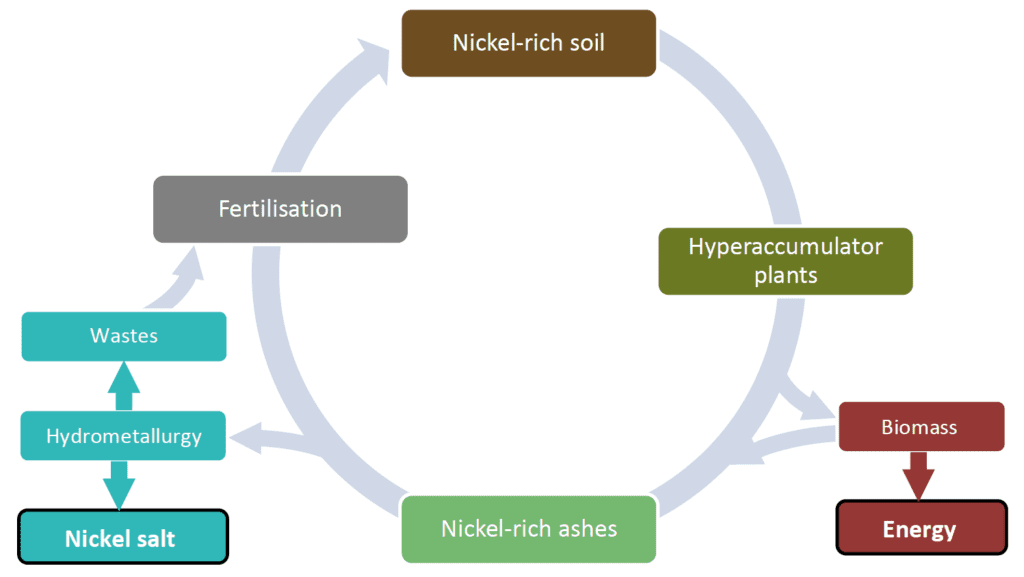

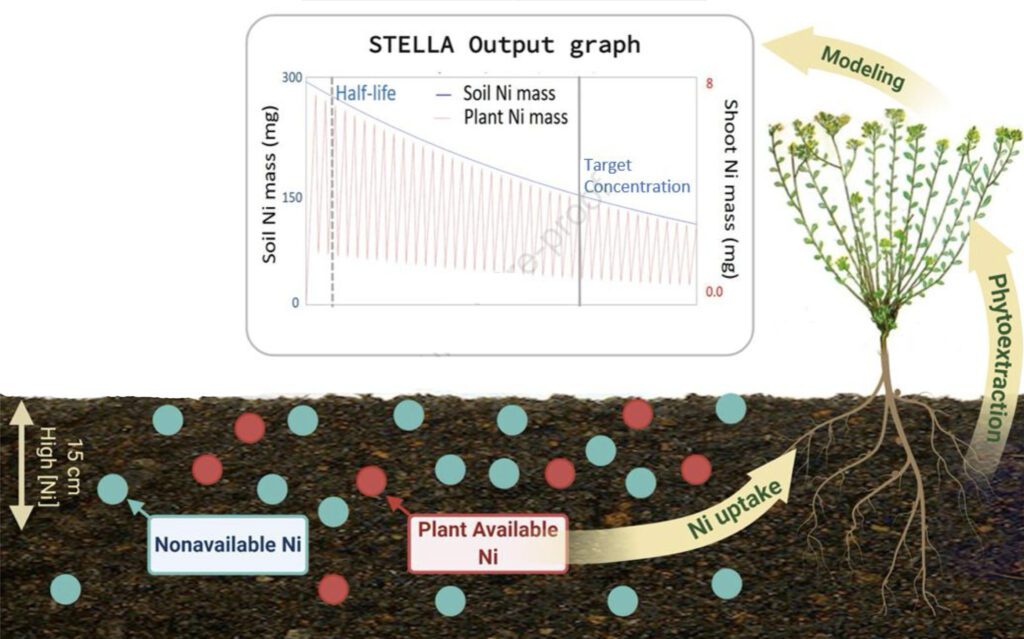

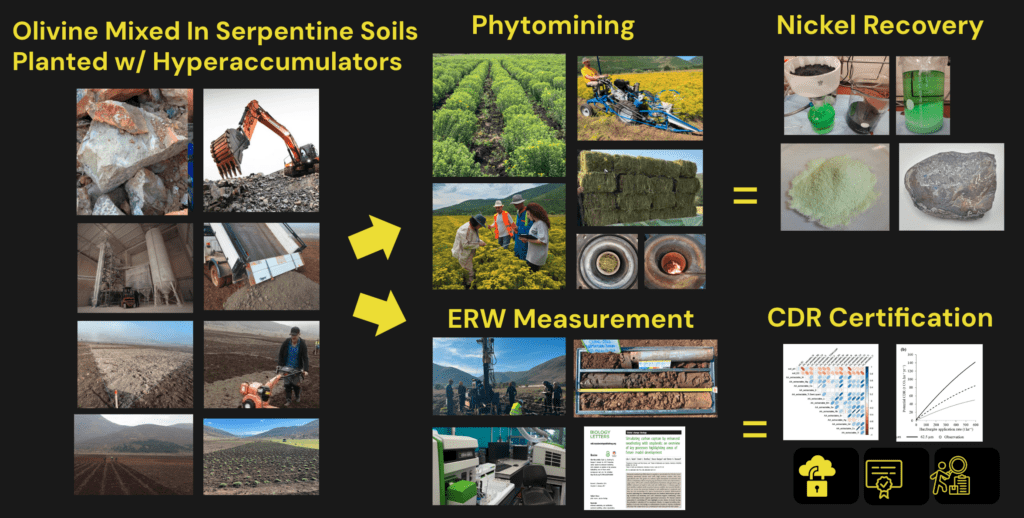

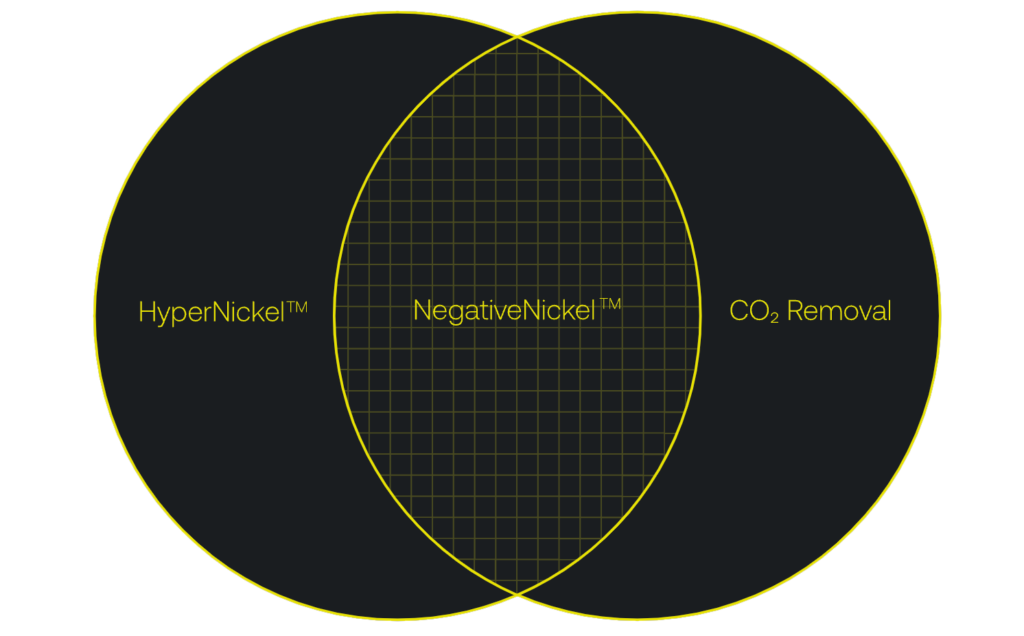

NegativeNickel™ is a combination of hyperaccumulated HyperNickel™ salt or ingot, along with a specified amount of carbon dioxide removal.

This sample is in a ratio of N1:CDR200, where for every 1 unit of nickel produced, 200 net units of carbon dioxide are net removed in the production of this product.

This is a 0.250 gram quantity of nickel salt or nickel ingot, of which 50 grams of carbon dioxide removal will be attributed, giving the nickel a carbon-negative footprint that can offset (or inset) the embodied emissions of the products it goes into. Welcome to the start of a carbon-negative world.

$45.00