Hyperweathering: Forging a Carbon-Negative Future with Critical Minerals and Enhanced Rock Weathering

Introduction: Addressing Intertwined Global Crises

Humanity stands at a critical juncture, facing the dual and interconnected crises of accelerating climate change and escalating resource scarcity. The scientific consensus, powerfully articulated by the Intergovernmental Panel on Climate Change (IPCC) and corroborated by the latest data from the World Meteorological Organization and Copernicus, confirms that 2024 was the warmest year on record, with the global average temperature exceeding 1.5°C above pre-industrial levels for the calendar year. Atmospheric carbon dioxide concentrations continue their relentless climb, reaching approximately 422.1 ppm in 2024. The Global Carbon Budget 2024 report underscores the urgency, revealing that global fossil fuel CO2 emissions hit a new record in 2024, leaving a perilously small carbon budget – estimated at roughly six years at current rates for a 50% chance of limiting warming to 1.5°C.

This stark reality necessitates a paradigm shift in our approach. The IPCC’s assessments make it unequivocally clear: deep emissions reductions alone are insufficient. We must actively develop and deploy scalable technologies for Carbon Dioxide Removal (CDR) to draw down legacy emissions and address hard-to-abate sectors. Concurrently, the vital transition to a green energy economy—our primary weapon in decarbonization—hinges on an unprecedented supply of critical minerals. The International Energy Agency (IEA) projects that demand for metals like nickel, lithium, and cobalt could skyrocket by up to 1,900% for nickel and 4,200% for lithium by 2040, as these are foundational to electric vehicles, battery storage, and renewable energy infrastructure.

Traditionally, these monumental challenges have been tackled in silos. Carbon removal strategies pursued avenues like direct air capture or afforestation, while critical minerals were sourced via conventional mining—a sector grappling with significant environmental and social footprints. Metalplant is charting a new, integrated course. We have pioneered “Hyperweathering,” a breakthrough approach that synergistically combines Enhanced Rock Weathering (ERW) with phytomining, not only to sequester atmospheric CO₂ but also to sustainably produce essential critical minerals with a net-carbon-negative footprint. Our flagship product, NegativeNickel™, embodies this vision.

This article delves into the robust scientific underpinnings of hyperweathering. It explores its profound potential for climate change mitigation, its positioning as a responsible geoengineering technique, and its pivotal role in fueling the green energy transition through the sustainable provision of critical minerals. Metalplant’s innovation represents a transformative step in how we conceive resource utilization and carbon stewardship, demonstrating that ecological restoration and industrial necessity can be mutually reinforcing.

The Science of Enhanced Rock Weathering: Accelerating Nature’s Carbon Sink

Natural Carbon Sequestration: Earth’s Slow Geochemical Thermostat

To appreciate the innovation of Enhanced Rock Weathering, one must first understand Earth’s natural long-term carbon cycle. The geological weathering of silicate rocks is a primary mechanism by which the planet has regulated atmospheric CO₂ over eons. When rainwater, slightly acidic from dissolved atmospheric CO₂, interacts with silicate minerals, a series of chemical reactions ensues. These reactions convert gaseous CO₂ into stable bicarbonate ions (HCO₃⁻). These ions are transported by rivers to the oceans, where marine organisms utilize them to form calcium carbonate shells and skeletons. Upon their demise, these organisms sink, eventually forming limestone and other carbonate rocks, effectively sequestering carbon for geological timescales – hundreds of thousands to millions of years.

This natural process, while profoundly important, operates on timescales far too slow to counteract the current anthropogenic surge in CO₂ emissions. Globally, natural silicate weathering is estimated to remove only about 0.3 gigatons of CO₂ annually, a small fraction of the over 40 gigatons emitted by human activities each year. Enhanced Rock Weathering seeks to dramatically accelerate this natural carbon sink to achieve climate-relevant CO₂ removal within human timescales. As the Department of Energy’s Carbon Negative Shot initiative highlights, developing cost-effective and scalable CDR solutions like ERW is paramount.

Metalplant’s Hyperweathering: A Synergistic Leap Forward

Metalplant’s proprietary hyperweathering process significantly advances ERW technology. Conventional ERW typically involves spreading crushed silicate rocks, such as basalt or olivine, onto agricultural lands, relying on natural processes for weathering and carbon sequestration. Hyperweathering, however, employs an actively managed, multi-faceted strategy to boost both the rate and overall efficiency of CO₂ removal, integrated with phytomining.

Our process meticulously begins with the sourcing and preparation of olivine, a magnesium iron silicate mineral ((Mg,Fe)₂SiO₄). Olivine is chosen for its relatively rapid weathering rate compared to other silicate minerals and its abundant global availability. Metalplant has secured exclusive access to a multi-billion tonne, high-purity olivine deposit (approximately 80% forsterite olivine, 0.33-0.343% nickel) adjacent to our Albanian operations, supplied at a very low cost by a co-founder. This olivine undergoes proprietary grinding processes to achieve an optimal particle size (sub-100 micron) that maximizes reactive surface area while managing potential dust. The process also includes mechanical gravimetric operations to remove loose chromite, at a net cost of approximately $4/tonne of olivine after accounting for potential chromium byproduct sales.

The processed olivine is then applied to carefully selected nickel-bearing serpentine soils – the native habitat of the hyperaccumulator plants we utilize. Metalplant’s innovation lies in moving the farm to the rocks, operating on ultramafic soils that are themselves derived from these minerals. We employ several interventions to accelerate weathering:

Optimized Application & Soil Interaction: We target substantially higher application rates (e.g., 100 tonnes/hectare) than some conventional ERW proposals. This is driven by the need to replenish nickel extracted by phytomining, but also contributes to potentially the highest density ERW-based carbon removal per land unit per year. The olivine is mixed into the soil where elevated CO₂ levels from root respiration and microbial activity, along with direct water exposure, accelerate dissolution.

Biocatalyst and Chelator Research: While the draft mentions partnerships with Sheffield University for microbial communities and the Leverhulme Centre for chelator-enhanced weathering, Metalplant’s provided background files also mention exploring iron chelators as a biotechnology to accelerate weathering, referencing a study showing a 2.5x increase in basalt weathering, suggesting even greater potential for pure olivine.

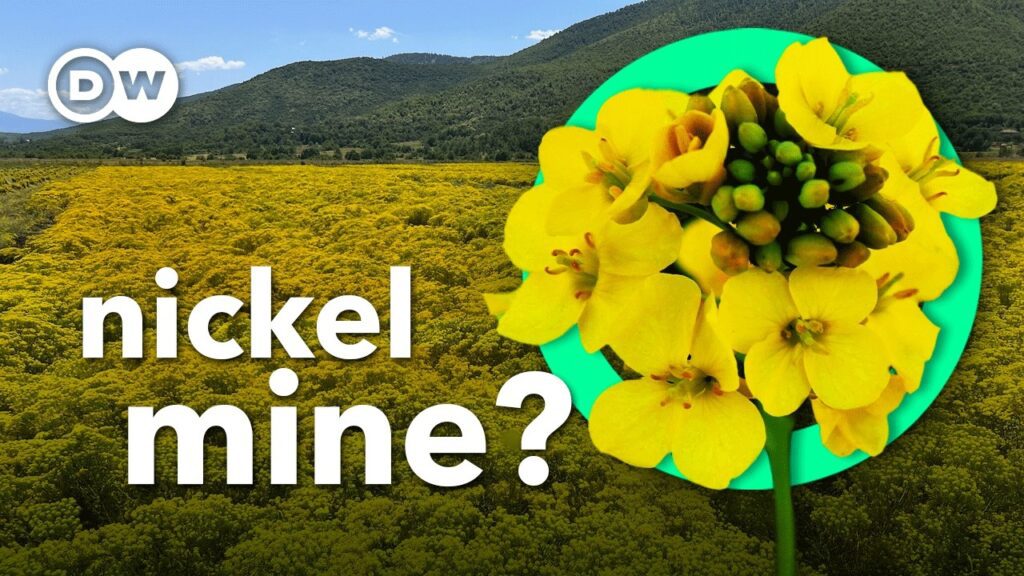

Hyperaccumulator Plant Integration (Phytomining): This is the cornerstone of Metalplant’s unique hyperweathering system. We utilize specific nickel hyperaccumulator plant species, particularly a perennial from the Brassicaceae family (related to Alyssum species like Odontarrhena decipiens), native to Albania, where our initial farms operate. These plants are extremophiles, capable of accumulating nickel in their tissues to concentrations exceeding 1-2% of their dry weight (our species can achieve >2%). This process is guided by decades of academic research and commercialization efforts, sometimes termed “agromining.”

The synergy is powerful: as olivine weathers, it releases magnesium and other cations, sequestering CO₂, and also releases trace nickel from its crystal lattice (our olivine contains ~0.34% nickel). The hyperaccumulator plants actively absorb this nickel. This phytoextraction of nickel can be seen as removing a reaction product, potentially shifting the chemical equilibrium to favor further olivine dissolution and weathering, as suggested by Le Chatelier’s principle. The annual nickel phytoextraction (e.g., >333 kg/ha/year ) is designed to be in equilibrium with the nickel released from the applied olivine (100 tonnes of olivine at 0.333% Ni releases 333 kg Ni when fully weathered), allowing for sustainable, long-term operations.

Carbon Sequestration Chemistry and Quantification

The primary carbon sequestration chemistry for olivine (specifically the forsterite component, Mg₂SiO₄) is:

Mg₂SiO₄ (olivine) + 4CO₂ + 4H₂O → 2Mg²⁺ + 4HCO₃⁻ + H₄SiO₄ (dissolved silicic acid)

Stoichiometrically, one tonne of pure forsterite olivine can remove approximately 1.25 tonnes of CO₂. Metalplant’s source rock, being ~80% olivine, thus has the potential to remove approximately 1 tonne of CO₂ per tonne of mineral applied.

The sequestered carbon is stored primarily as bicarbonate ions dissolved in water, which eventually make their way to the ocean, increasing its alkalinity and contributing to long-term carbon storage with durability estimated at 10,000-100,000 years.

Robust Measurement, Reporting, and Verification (MRV) is critical. Metalplant is working with EcoEngineers to develop a combined Enhanced Weathering & Phytomining Methodology, compliant with ISO 14064-2 and existing ERW methodologies like Puro.earth’s. Puro.earth itself is actively updating its ERW methodology to incorporate the latest scientific advancements. Metalplant’s MRV approach includes:

Soil pH and alkalinity measurements pre- and post-application.

Lysimeters for in-situ soil water analysis.

Monitoring of downstream water systems.

Life Cycle Assessments (LCA) accounting for emissions from rock grinding (using 100% renewable hydroelectric power in North Albania), transport, and other operational aspects.

Potential use of advanced MRV techniques from partners, with trials planned.

Metalplant’s initial field trials demonstrate high carbon sequestration efficiency, with the target of producing verifiable, high-permanence carbon removal credits. The unique integration of high-CO₂ potential minerals (olivine) at higher application rates aims for greater CO₂ removal per hectare and higher overall efficiency than many other ERW proposals.

Climate Mitigation Potential and Recent Scientific Context

The Unmistakable Need for Carbon Dioxide Removal

The latest scientific assessments from the IPCC (Sixth Assessment Report and ongoing AR7 cycle) and annual updates like the Global Carbon Budget paint a sobering picture: global climate targets are increasingly out of reach without large-scale Carbon Dioxide Removal (CDR). Pathways limiting warming to 1.5°C now inherently involve removing hundreds of gigatons of CO₂ from the atmosphere this century. This imperative is driven by historical emissions, the challenge of decarbonizing certain sectors (e.g., agriculture, heavy industry, aviation), and the prospect of overshooting climate targets. The UN Environment Programme’s (UNEP) Adaptation Gap and Emissions Gap reports consistently highlight the growing chasm between current actions and what’s needed. Recent analyses suggest the US alone might need to remove 0.5 to 2.4 GT CO₂/year by 2050 to achieve net-zero.

While natural sinks like forests and oceans absorb significant CO₂, they are under pressure from climate change itself. Engineered CDR solutions, though rapidly innovating, currently remove a tiny fraction (less than 0.01 gigatons annually) of what’s needed. This underscores the urgent need to scale up effective, verifiable, and durable CDR technologies.

Metalplant’s Hyperweathering: A Scalable, Durable CDR Solution

Metalplant’s hyperweathering approach offers distinct advantages that position it as a significant contributor to the CDR landscape:

Scalability: Hyperweathering leverages agricultural systems. Metalplant is initially operating in Albania, where 10% of soils are naturally nickel-bearing and hyperaccumulator species are native, with over 1 million hectares of suitable land in the Balkan region. The company plans global upscaling, including to the US, facilitated by an ARPA-E grant to develop non-GMO, sterile, high-yield hyperaccumulator cultivars suitable for American soils. The potential to use existing agricultural infrastructure and marginal lands reduces deployment barriers.

Durability of Sequestration: Carbon stored as dissolved bicarbonates via mineral weathering offers high permanence (10,000-100,000 years), a critical factor increasingly valued in carbon markets. This contrasts with some nature-based solutions that are more vulnerable to reversal.

Co-production of Value: The simultaneous production of critical minerals (NegativeNickel™) creates an additional revenue stream, improving the economic viability of the CDR operation. Metalplant’s model aims for profitability without necessarily relying on green premiums for nickel or high carbon credit prices, though these enhance margins. This is a unique advantage, as many CDR methods currently require subsidies.

Environmental Co-benefits: Beyond CDR and nickel, the process can improve soil health on nickel-bearing soils, which are often low-productivity for traditional crops. The wind-down plan for projects includes continued phytomining after ceasing olivine addition to remediate nickel levels, potentially making land suitable for other crops.

Metalplant’s Albanian field trials and planned commercial trials (Spring 2025) are designed to validate carbon removal efficacy (targeting 100 net tonnes CO₂ removed per tonne of nickel) and the overall process economics.

Market Dynamics: The Rise of High-Durability Carbon Removal

The voluntary carbon market is maturing, with a clear trend towards favoring high-quality, durable carbon removal credits. Initiatives like Microsoft’s carbon negative goals, Stripe’s Frontier fund, and corporate purchases of ERW credits (e.g., Microsoft’s deal with Terradot) signal strong demand for verifiable and permanent CDR. Metalplant is positioning itself to meet this demand by developing its MRV system with EcoEngineers to be compliant with standards like Puro.earth, which are themselves evolving with scientific advancements. Metalplant has a partner with pre-sold CDR tonnage looking to use Metalplant’s fast-weathering minerals and MRV for fulfillment, indicating a ready market pathway.

Responsible Geoengineering: ERW’s Role in Climate Intervention

Understanding the Geoengineering Landscape

Geoengineering, the deliberate large-scale intervention in Earth’s climate system to counteract climate change, is a term that encompasses a wide array of technologies with varying risk profiles and societal implications. It is broadly divided into two categories:

Solar Radiation Management (SRM): Aims to reflect a small fraction of incoming sunlight back to space to cool the planet. Examples include stratospheric aerosol injection (SAI), marine cloud brightening. SRM techniques do not address the root cause (atmospheric CO₂ concentrations) and raise significant concerns about potential side effects, termination shock, and governance. Recent scientific and policy discussions reflect deep caution, with some calls for moratoria on outdoor experiments and even bans.

Carbon Dioxide Removal (CDR): Focuses on removing CO₂ from the atmosphere and storing it durably. ERW, afforestation, direct air capture (DAC), and bioenergy with carbon capture and storage (BECCS) fall under this category.

Enhanced Rock Weathering, and Metalplant’s hyperweathering, are firmly within the CDR camp. Many scientists and institutions, including the National Academies of Sciences, Engineering, and Medicine, view ERW as a “lower-risk” or “no-regrets” geoengineering option because it accelerates natural Earth processes to address the fundamental driver of climate change – excess atmospheric CO₂.

ERW: A Considered Approach to Climate Intervention

ERW stands out as a more responsible geoengineering method due to several key characteristics:

Mimicking Nature: It enhances natural geological weathering, rather than introducing entirely novel atmospheric manipulations.

Localized and Controllable: Application is regional, allowing for monitoring and adaptive management. If necessary, application can be ceased without the abrupt termination risks associated with some SRM methods.

Addresses Root Cause: It directly removes CO₂ from the atmosphere.

Co-Benefits: Offers advantages beyond carbon removal, such as soil health improvements and, in Metalplant’s case, sustainable mineral production and land remediation.

Quantifiable Results: Carbon sequestration can be measured and verified through scientific protocols, ensuring transparency. Metalplant is actively working on this with EcoEngineers and potential MRV partners.

Environmental Stewardship and Safety

Responsible deployment is paramount. Metalplant’s approach incorporates several environmental safeguards:

Mineral Sourcing and Purity: Using high-purity olivine from a dedicated source and processing it to remove impurities like excess chromite.

Targeted Application: Operating exclusively on existing nickel-bearing ultramafic soils, where the applied minerals are geochemically similar to the native soil composition.

Water Quality Monitoring: Implementing strict watershed monitoring to track any potential transport of heavy metals, ensuring protection of water resources. The energy grid for initial operations in Albania is 100% renewable hydropower.

Dust Management: While the draft mentions precision particle size and encapsulation, Metalplant’s background mentions planning for wet grinding and slurry application to minimize dust and improve distribution efficiency, inspired by mining and farming practices.

Land Remediation Goal: The phytomining aspect, especially in the wind-down phase, aims to leave soils with lower nickel levels than their initial natural state, potentially improving them for other agricultural uses.

Scaling with Responsibility

While ERW has significant global potential, scaling requires careful management of mineral supply chains, land use, logistics, and economics. Metalplant’s vertical integration, including access to its own olivine resource and plans for efficient slurry-based mineral distribution, aims to address these challenges. The economic model, with dual revenue streams from nickel and CDR, is designed to be resilient.

Green Energy Transition: Hyperweathering the Critical Mineral Bottleneck

The Insatiable Demand for Clean Energy Metals

The global shift to a green energy economy is, fundamentally, a shift in material requirements. Technologies like electric vehicles (EVs), wind turbines, solar panels, and large-scale battery storage demand vast quantities of specific minerals far exceeding those needed by their fossil fuel counterparts. The IEA and other analysts project dramatic increases in demand for lithium, cobalt, graphite, and particularly nickel – a key component in high-performance EV batteries (e.g., NMC and NCA cathodes typically contain 60-80% nickel) and other clean energy applications.

Meeting this surge through conventional mining alone presents formidable challenges:

Environmental Degradation: Including deforestation, habitat loss, vast water consumption, and the generation of toxic tailings (e.g., concerns around Indonesian nickel laterite mining, which often involves deforestation and coal-fired processing, producing significant waste and CO₂ emissions).

Carbon Footprint: Conventional nickel production is energy-intensive, emitting, on average, 13-18 tons of CO₂ per ton of nickel.

Long Lead Times: New mines can take 10-20 years to become operational, creating potential supply bottlenecks that could slow the energy transition.

Geopolitical Concentration: Supply chains for many critical minerals are concentrated in a few regions, leading to supply security concerns.

Metalplant’s NegativeNickel™: A Sustainable Mineral Revolution

Metalplant’s hyperweathering process offers a revolutionary alternative for sourcing critical minerals, exemplified by our NegativeNickel™. Instead of disruptive extraction, we cultivate metals:

Mineral Application & Weathering: Olivine is applied to agricultural land, initiating ERW and CO₂ sequestration.

Phytoextraction: Nickel hyperaccumulator plants (our selected Brassicaceae species) absorb the nickel released during olivine weathering, concentrating it in their biomass to levels of 1-2% or more (ash can be >20% nickel, comparable to rich ores).

Harvest & Processing: The biomass is harvested. Metalplant is developing and optimizing hydrometallurgical techniques with expert metallurgists to efficiently extract nickel from the plant material and convert it into battery-grade Nickel Sulfate Hexahydrate (NiSO₄, 22.3% Ni), a direct precursor for EV battery cathodes, or into feedstock for stainless steel.

Carbon-Negative Product: The resulting NegativeNickel™ has an inherently negative carbon footprint. For every tonne of nickel produced, the integrated hyperweathering process is designed to sequester over 100 net tonnes of CO₂. This offers a stark contrast to the carbon-positive footprint of conventionally mined nickel.

Fueling Green Technologies with Clean Minerals

NegativeNickel™ is chemically identical to conventionally produced nickel but its negative carbon footprint provides a compelling advantage for:

Electric Vehicle Batteries: Significantly reducing the embodied carbon of EVs, helping manufacturers achieve true net-zero vehicle production. Metalplant has garnered interest from major automotive and EV battery cathode suppliers. If processed in the US, it could also be IRA-compliant.

Renewable Energy Storage: Providing sustainable nickel for grid-scale batteries.

Green Hydrogen Production: Supplying nickel for electrolyzers.

Other Advanced Technologies: Including next-generation solar cells.

Competitive Edge in Mineral Production

Metalplant’s phytomining-ERW approach offers key advantages:

Drastically Reduced Environmental Impact: Avoids deforestation, large pits, toxic tailings, and high water use associated with conventional mining. It offers a sustainable alternative to practices like Indonesian laterite mining.

Superior Carbon Footprint: Turns a major emissions source into a carbon sink.

Land Restoration: Can be deployed on marginal or nickel-bearing lands, improving soil health over time. The initial focus is on existing nickel-bearing soils, with a plan to leave them remediated.

Faster Scalability: Farms can be established and productive in months to a few years, much faster than traditional mines.

Economic Viability: The dual revenue streams from high-value nickel and carbon removal credits create a robust business model. Operating costs for phytomining are projected to be competitive.

Domestic Supply Potential: The ARPA-E grant supports developing plant cultivars for the US, aiming to create a domestic green nickel industry, addressing supply chain security.

Spring 2025 Commercial Trial and Beyond

Metalplant is advancing towards a significant commercial trial in Spring 2025. This will implement multiple advanced MRV techniques compliant with Puro’s ERW Methodology and will involve a partner’s MRV technique to validate weathering rates, paving the way for larger-scale deployment. The goal is to demonstrate commercial viability and begin fulfilling demand for both NegativeNickel™ (with an intermediate target of 100,000 tonnes/year from ~50,000 hectares) and CDR credits.

Conclusion: A Symbiotic Path to a Sustainable Future

The intertwined crises of climate change and resource depletion demand solutions that are not just innovative but integrative. Metalplant’s hyperweathering technology embodies this principle, offering a pathway to simultaneously remove atmospheric carbon dioxide at scale and sustainably produce the critical minerals vital for the global transition to green energy. This is not merely an incremental improvement but a fundamental re-envisioning of how industrial processes can work in concert with, and to the benefit of, natural systems.

The scientific bedrock of hyperweathering—marrying the geochemistry of enhanced rock weathering with the biological power of phytomining—is robust and validated by ongoing field research. Our operations in Albania, leveraging native hyperaccumulators on endemic nickel-rich soils and powered by renewable energy, serve as a living laboratory and a blueprint for future expansion. The upcoming commercial-scale trials in 2025 are poised to demonstrate the scalability and economic soundness of this carbon-negative metal production system.

The urgency dictated by the latest climate science—record global temperatures, dwindling carbon budgets, and the now undeniable necessity for gigatonne-scale CDR—cannot be overstated. Metalplant is responding to this call by offering a solution that is not only scalable and its carbon sequestration highly durable, but also one that directly addresses a critical bottleneck in the green energy transition: the sustainable supply of essential metals like nickel.

Our vision extends beyond current operations. Future developments include:

Continuous Process Optimization: Further enhancing carbon sequestration efficiency and metal recovery rates through ongoing R&D in plant genetics (supported by our ARPA-E grant), microbial symbioses, and advanced mineral processing.

Diversified Mineral Portfolio: Expanding our phytomining capabilities to recover other critical minerals.

Global Implementation & Research Hubs: Establishing “Silicate Valleys” – regional centers for hyperweathering and advanced olivine/serpentine weathering research – in suitable geological and climatic zones worldwide, fostering a distributed network of carbon removal and sustainable metal production.

Policy and Market Leadership: Actively contributing to the development of robust MRV standards and advocating for policies that accurately value permanent carbon removal and sustainably sourced critical materials. We plan to contribute data to initiatives like the Cascade ERW Data Quarry and open-source aspects of our upscaling plans.

Metalplant’s hyperweathering is more than a technology; it’s a new paradigm where resource extraction actively contributes to planetary healing. We are demonstrating that ecological responsibility and industrial productivity can be powerful allies. We invite researchers, policymakers, investors, and industry leaders to collaborate with us in scaling this transformative solution, building a future where the foundations of our green economy are forged with carbon-negative materials, contributing to a stabilized climate and a truly sustainable civilization..