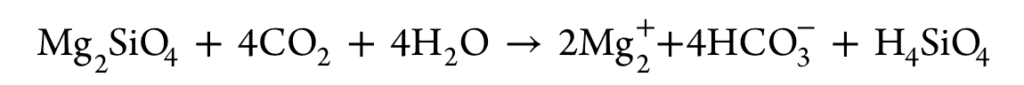

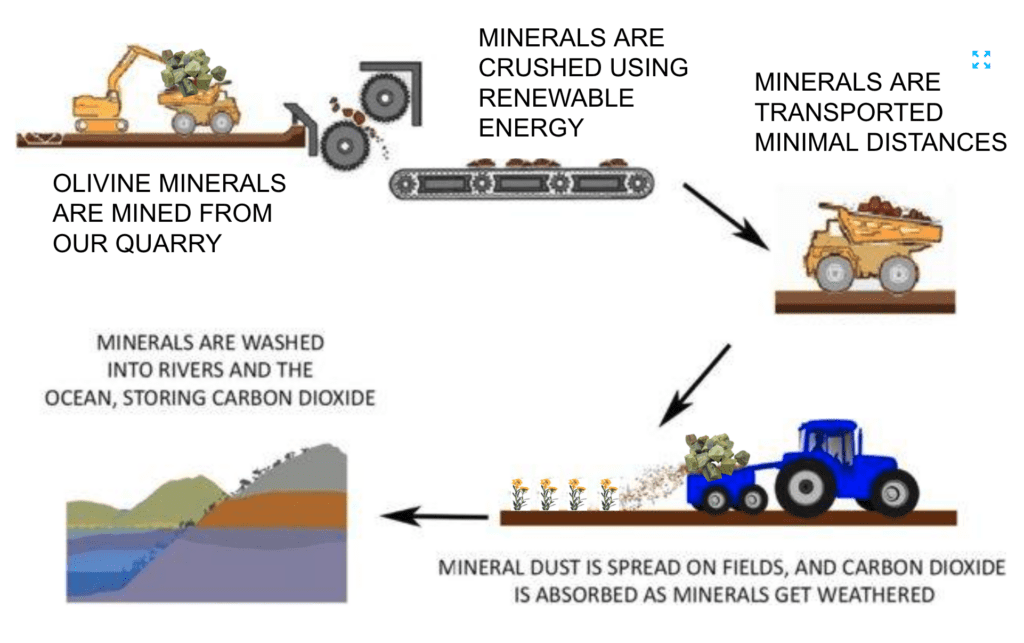

HyperWeathering™ Carbon Dioxide Removal through Enhanced Rock Weathering While Phytomining

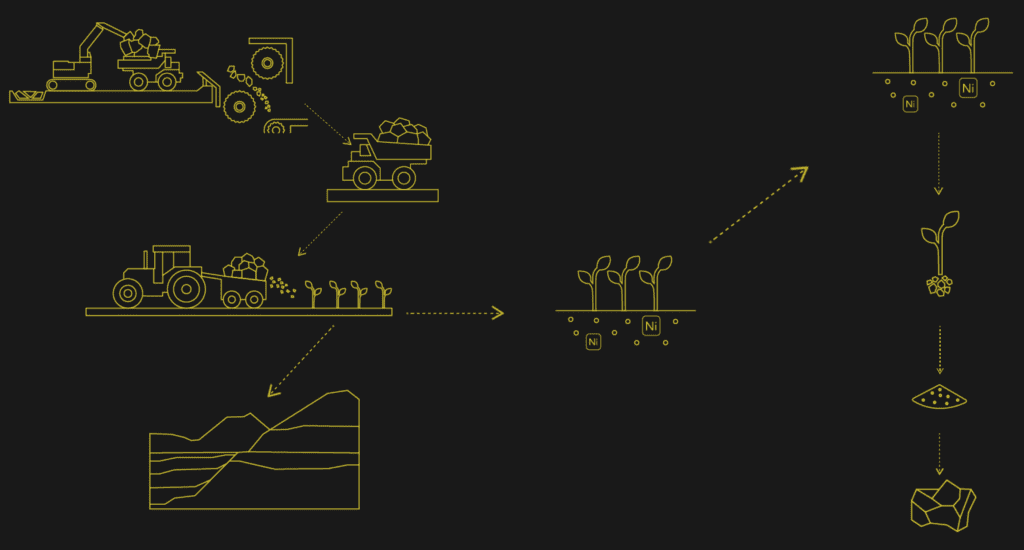

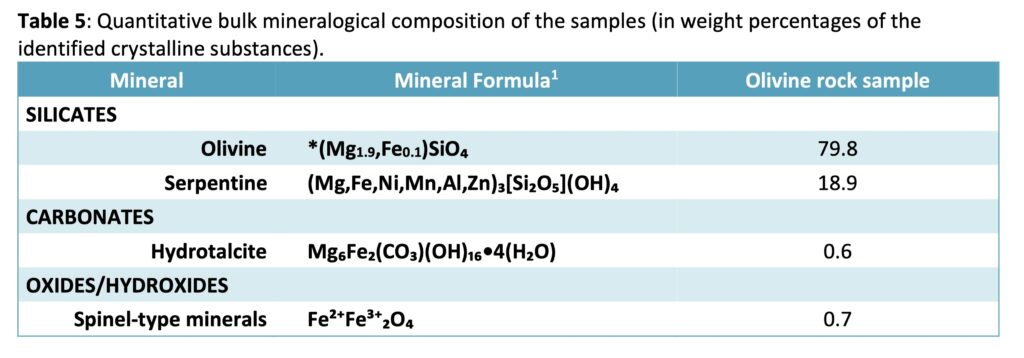

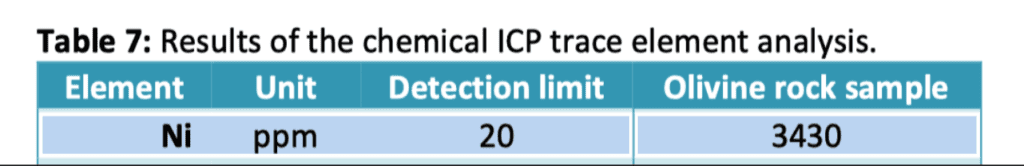

HyperWeathering™ Carbon Dioxide Removal (CDR) occurs though the enhanced rock weathering (ERW) of olivine on our hyperaccumulator farms, while we carry out phytomining. For every 300 tonnes of olivine fully weathered, approximately 1 tonne of nickel is liberated from the mineral as it dissolves.

This release of nickel into soils during ERW has previously prevented the usage of olivine at relevant application rates. Metalplant operates on naturally nickel-bearing serpentine soils and then plants nickel hyperaccumulator plants to both recover existing and released nickel as the plants grow and the rocks weather.

Any carbon-removal not allocated to our NegativeNickel product will be made available directly, with a greater than 70% efficiency in combined ERW+Phytomining, each 1 tonne of nickel supplied by olivine equates to the removal of 200 net tonnes of carbon dioxide removal.

HyperWeathering™ is currently only publicly available through the NegativeNickel™ product, though we are taking direct inquiries for large CDR off take ad future purchases directly.

$99.99

Out of stock